Slide-Lag®

REPLACEABLE

Pulley Lagging for Drive Pulleys…

Superior Traction for Conveyor and Elevator Systems

ENGINEERED LAGGING

for engineered conveyor & elevator systems

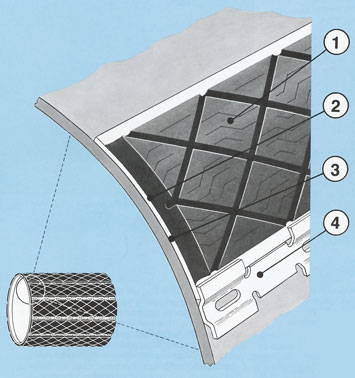

HOLZ Slide-Lag® traction pads – a unique and proven method of increasing

conveyor and elevator performance. Designed for direct application to the drive pulley, this product can transform any belt system into a high performance,

low-maintenance operation. In addition to providing outstanding increases in the coefficient of friction (traction) between the belt and pulley, it serves to protect the pulley face and belt cover from damage and provides a self-cleaning action to prevent material build-up on the pulley.

Slide-Lag’s® combination of elastomer compounds and product design features is consistently superior to conventional vulcanized, cold bond or bolted-on pulley laggings. Unique factory bonding system eliminates lagging separation thus making Slide-Lag® ideal for severe service conditions with dual or high horse-power drives or using steel cable conveyor belts. The MSHA approved SOF compound provides an added margin of safety for potentially hazardous operations in underground mining and meets OHSA standards for grain and fertilizer handling.

The SLIDE-LAG® Formula…

provides specially compounded elastomer padding vulcanized under high

pressure to heavy-gauge steel plates which are shaped to conform to each

pulley face. The plates slide in and out of special retainers which have been

securely welded or bolted to the pulley face.

- Exclusive elastomer compounding provides a lagging pad with exceptional drive-pulley traction, abuse resistance, and extra long service life. The elastomer retains its integrity under the most severe operating conditions.

- Factory hot-vulcanization under pressue assures the best possible bond of rubber to backing plate. No lagging failures from loss of adhesion and separation – the most common problems associated with conventional lagging.

- Steel backing plates are precision formed at the factory to fit the curved surface provided by each individual pulley diameter. Insures proper pad stability and long life.

- Rust-resistant metal retainers are permanently welded or bolted to the pulley face to securely hold the lagging pads in place. When properly installed, lagging cannot shift or pull free from the effects of impact, trapped material, or belt or product movement.

These four special features make Slide-Lag® products the most unique and reliable system for lagging all conveyor and elevator pulleys. Slide-Lag® can be installed on the job, usually without removing either the belt or pulleys from the system. Eventual replacement of worn or damaged pads is even quicker and easier, since the retainers are already in place.

The Economy of Readily Available SLIDE-LAG®

Slide-Lag® is inventoried in standard factory produced lengths by authorised HOLZ stocking distributors. This offers system owners new economies by eliminating the need for in-plant stocks of lagging and/or extra lagged pulleys. Owners may also economize by installing the lagging themselves, using either of the following methods of application: (1) The ‘butt seam’ method, which utilises all material cut from full pad lengths. The ends of each cut piece are butted together. Butt seam application is usually the most economical approach to use. (2) The ‘full width’ method, in which each pad row is provided with full face width pads that have no butt seams (except on pulleys over 72″ wide, where a butt seam is used at the pulley center line). Absence of butt seams is attractive, but offers no performance advantage over the less costly butt seam application method.

SLIDE-LAG®

lowers maintenance costs

SUPERIOR TRACTION

Slide-Lag®’s rubber compounding and tread-like surface which combines double chevron grooves and shallow slits on individual pads promote belt drive and maximum traction. Slide-Lag® has proven superior to all other lagging methods in a wide variety of applications throughout the world. This is particularly true where drive-pulley slippage has been a problem.

LONGER LIFE

The retainers which form an integral part of the HOLZ Slide-Lag® installation method provide a strong, virtually unbreakble bond between the lagging and pulley face. This exclusive feature eliminates costly lagging failures from separation and loss of adhesion, and insures years of trouble-free performance. Pads are locked in place to prevent lateral movement using simple procedures outlined in Slide-Lag® installation instructions.

ABUSE RESISTANCE

Slide-Lag® is fabricated from top quality, abrasion-resistant elastomers to a maximum practical thickness capable of withstanding the most severe operating conditions. Consequently, failures from rubber tearing or gouging are dramatically reduced, and maintenance costs are kept at a minimum.

SLIDE-LAG®

minimises downtime

EASY INSTALLATION

Slide-Lag® can normally be installed without removing the pulleys from operating position or opening the belt splice. Simply release belt tension to allow pulley rotation, attach retainers, slide and lock pads in place, tighten belt and resume operation. Slide-Lag® will effectively replace other types of lagging using the same clean-up procedures that are always required to remove other types of old lagging. However, once Slide-Lag® is installed, future clean-up problems for lagging replacement are eliminated. When ordering new equipment, specify Slide-Lag® replaceable lagging for pre-installation prior to delivery.

QUICK REPLACEMENT

Replacing Slide-Lag® is even more convenient and easier to do, since the retainers are already in position. High costs generated by pulley removal for shipment to a rubber fabricator just to have lagging replaced are permanently erased. If scheduled maintenance time is limited, pads can be replaced a few at a time during the brief shutdowns that always occur during day-to-day operation.

SELF CLEANING

Slide-Lag®’s unique combination of double chevron grooves, shallow slits and individual pads results in a kneading or flexing action that actively resists material build-up. Foreign material works its way to the edges of the pulley through the channels between the pads where it falls away. This continuous, built-in- self-cleaning action keeps material build-up problems down, and associated belt tracing troubles virtually disappear.

Use SLIDE-LAG® EDGE-CROWN®

to create a crown on a flat-face drive pulley

Standard conveyor engineering usually calls for a crowned surface on all drive pulleys. A crowned pulley is used to assist in tracking the belt or directing it back to the pulley centre when the belt starts to wander. Eliminating erratic lateral belt movement is important in preventing damage to the belt caused by contact with the structure.

HOLZ Edge-Crown® transforms a flat-face pulley into a crowned configuration. Edge-Crown® lagging creates a barrel-shaped crown that eliminates the high belt stress, scrubbing, and resultant wear associated with centre crowned pulley designs. Installation is accomplished with Slide-Lag® pads in the centre of the pulley and tapered Edge-Crown® pads on the sides.

Edge-Crown® also gives you:

- Superior traction

- Longer life and great abuse resistance

- Self-cleaning action

- Quick and easy installation and replacement

See diagram below for more detail on producing a crowned pulley with Slide-Lag® Edge-Crown®

PADS

Authorised HOLZ stocking distributors carry inventories of standard pads, complete with required retainers, for application by system owners using the ‘butt seam’ or ‘full width’ method.

Slide-Lag® traction pads with standard 60 durometer industrial compound for use on drive pulleys, in 72″ lengths, formed to specific pulley diameters. Also available in all special compounds with or without stainless steel (SS) backing plates. NOW AVAILABLE IN HUSKY.

Slide-Lag® traction pads with standard 60 durometer industrial compound for use on drive pulleys, in 72″ lengths, formed to specific pulley diameters. Also available in all special compounds with or without stainless steel (SS) backing plates. NOW AVAILABLE IN HUSKY.

Slide-Lag® Edge-Crown® traction pads with standard 60 durometer industrial compound for use on drive pulleys, in 10″ lengths, formed to specific pulley diameters. Normally used in combination with Style 5 pads to provide a crown on a flat face drive pulley. Also available in all special compounds and standard or stainless steel (SS) backing plates. NOW AVAILABLE IN HUSKY.

Slide-Lag® Edge-Crown® traction pads with standard 60 durometer industrial compound for use on drive pulleys, in 10″ lengths, formed to specific pulley diameters. Normally used in combination with Style 5 pads to provide a crown on a flat face drive pulley. Also available in all special compounds and standard or stainless steel (SS) backing plates. NOW AVAILABLE IN HUSKY.

SETS

Assembled ready-to-install sets for a specific pulley are readily available from Enpro Industries, complete with retainers. Designed for ‘full width’ application method.

Slide-Lag® pulley traction pads with standard 60 durometer industrial compound, in complete sets, cut to length and formed for specific pulley diameter, ready to install. For special service conditions select a special compound with or without stainless steel (SS) backing plates.

Slide-Lag® pulley traction pads with standard 60 durometer industrial compound, in complete sets, cut to length and formed for specific pulley diameter, ready to install. For special service conditions select a special compound with or without stainless steel (SS) backing plates.

Complete set of Edge-Crown® and Slide-Lag® traction pads which together will completely cover a specific pulley diameter and face width. Same compound as Styles 5 and 7. Ready to install. Use special compounds and/or stainless steel (SS) backing plates for special service conditions.

Complete set of Edge-Crown® and Slide-Lag® traction pads which together will completely cover a specific pulley diameter and face width. Same compound as Styles 5 and 7. Ready to install. Use special compounds and/or stainless steel (SS) backing plates for special service conditions.

SPECIAL SERVICE CONDITIONS

require special SLIDE-LAG® and EDGE-CROWN®

GENERAL INFORMATION

As with all non-standard or ‘special’ applications, many variables must be taken into account when selecting an appropriate pulley lagging product to give ultimate service life. The information below is intended to provide general guidance for the selection of special service SLIDE-LAG® components. For any specific application, contact us for verification of the specification selected.

These special materials are available with all SLIDE-LAG® products, including EDGE-CROWN® and BELT-SAVER® EDGE-CROWN®.

SOF – STATIC CONDUCTIVE/OIL RESISTANT/FLAME – STOP

Static Conductive, Oil Resistant and Flame Stop properties are combined into an exclusive compound that reduces the risk of explosion, fire and oil-related lagging failure. Static electricity that may accumulate on the belt is allowed to drain off through the ladding to ground (in a properly grounded system), helping to reduce the danger of dust explosion. Oil resistance of this compound allows use in moderately oily applications involving the presence of certain hydrocarbons, fats, oils, greases, hydraulic fluids, solvents and moderate chemicals. The outstanding self-extinguishing characteristics of the SOF compound make it ideal for use in grain and fertilizer handling applications and meets the OSHA standards for static conductivity. The SOF compound has also received MSHA approval for use in underground mining applications. SOF meets the following:

- RMA1 test 808.1 for static conductivity

- RMA1 test 809.1 for flame resistance

- ASTM2 D991 for static conductivity

- MSHA3 approved compound for underground use

NOTE: Where MSHA approved compounds is required, specify ID #1C-97/2 when ordering.

Specify SOF with Style Number.

-

FS – FLAME-STOP

Flame-Stop should be used where self-extinguishing characteristics are of major benefit, such as underground coal-mining and grain fertilizer handling operations. Flame-Stop compound meets the test requirements established for conveyor belting under RMA1 test 809.1 for flame resistance and has received MSHA3 approval for use in the underground mining. Where MSHA3 approved compound is required, please specify:

- ID #1C-97/1 for 65 durometer Slide-Lag® Flame-Stop.

- ID #1C-97 for 40 durometer Belt-Saver® Flame-Stop.

Specify FS with Style Number

-

BN – BUNA-N

SLIDE-LAG® with BUNA-N (BN) compound is especially suitable for applications involving the presence of certain hydrocarbons, fats, oils, greases, hydraulic fluids and chemicals. It will also withstand moderate temperatures. Specify BN with Style Number.

-

EP – HEAT RESISTANT (EPDM)

Heat resistant (EP) SLIDE-LAG® should be selected for pulley lagging applications involving continuous operating temperatures in the range of 250o F or intermittent temperatures to 350o F. EPDM also offers advantages in the presence of certain unusual materials such as animal or vegetable oils and strong or oxidizing chemicals. Specify EP with Style Number.

-

HY – CHEMICAL RESISTANT (HYPALON)

Conveying or elevating applications involving some chemicals, alkaline solutions, freon, alcohols, hydrogen, aliphatic hydrocarbons and moderate temperatures are all potential candidates for the use of SLIDE-LAG® with Hypalon (HY) compound. Specify HY with Style Number.

-

“HUSKY” (HEAVY DUTY PADS)

“HUSKY” SLIDE-LAG® pads are designed for use in especially severe operating conditions to increase total pad life and reduce belt slippage. These pads are 3/4″ nominal overall gauge compared to the standard 9/16″ to resist abrasion and gouging, and increase the ‘gripping’ action of the pad to the belt. “HUSKY” may be produced with any available compound and stainless steel backing plates if required. Specify “HUSKY” Pad with Style Number and Compound Designation.

-

SS – STAINLESS STEEL

All standard and special elastomer compounds for SLIDE-LAG® are available with Stainless Steel (SS) backing plates and retainers. Type 304 stainless steel is provided unless otherwise specified. SLIDE-LAG® using stainless steel is recommended for highly corrosive environments such as coke ovens and fertilizer and chemical plants – often in conjunction with one of the special compounds show above. Specify SS with Style Number and Compound Designation.

- Rubber Manufacturers Association

- American Society for Testing and Materials

- Mine Safety and Health Administration

- Individual compounds FS, SC and OR have been discontinued and replaced by combination compound SOF.

Get in Touch

ENPRO INDUSTRIES

PO Box 1559

Bunbury WA 6231

CONTACT

Tel: 08 9725 9923